Dumpers

Part II

By Ken Hutchins, Josh Trentine, Gus Diamantopoulos, & Al Coleman

In this Installment

In Part I of our Dumpers series, we explored the history of negative hyperloading, starting with its emphasis by Arthur Jones as he used it to combat isokinetics philosophy in the early 1970s.

As we have already been discussing, Arthur made negative-only, negative-accentuated, and negative-emphasized exercise protocols very popular within the strength-training crowd. At one point Casey Viator sported a T-shirt that embodied this popularity. Across his chest it read, “Negatives are In!”

In Part II, we closely examine the issue of friction in exercise equipment, especially in the early Nautilus® days, that gave rise and continued sustenance to the false need for negative hyperloading.

Note that some of this information was originally slated for Volume II of The Renaissance of Exercise. However, we believe that the serious concern regarding the dangers and fallacies of the dumpers requires the urgent release of a minimum of these details.

To Continue:

Non-Weight-Stack Friction

Few of the Nautilus old guard recognize that although Arthur Jones taught his nephew, Scott LeGear, to weld, the vintage Nautilus machines were mostly prototyped by Scott, not Arthur. These machines are identified by their right-angled welds instead of the bent tubing that came out of the Virginia manufacturing plant after 1978 and the Mexia plant after 1982.

The statement above is not meant to indicate that Arthur was not original with many germs and not involved with many details leading to their fruition. He certainly was in most cases. However, it was mostly Scott that prototyped the ideas off Arthur’s I-HOP napkins to production. In fact, Arthur and Scott often argued heatedly regarding designs. To the outsider, these arguments sounded as though the two men were about to kill each other. These arguments almost always ended in peaceful and very productive resolutions.

One principle by which Scott worked was that it was crucial to eliminate as many redirectional sprockets as possible from every design. (This principle is still valid.) This was based on Scott’s assertion that each additional sprocket roughly doubled the magnitude of machine friction. This varied case by case, of course, depending on the degree of redirection caused by the sprocket. For example, a sprocket that redirected the chain 180 degrees produced much more friction than another that barely deviated the straightness of the chain.

Scott’s friction challenge was not just the addition of sprockets. Even worse was the fact that all of these sprockets spun on inferior oil-impregnated bronze bushings (OIB).

A bushing provides an articular surface for a rotating part. It is placed between a rotating part and the machine frame. And although it prevents wear on the steel parts and does reduce friction between these parts up to a point, it does not reduce friction to the degree that proper bearings do. (Note that to confuse things more, some documents refer to “bushings” as “bearings” and some refer to “bearings” to “bushings.” Some even refer to “ball bearings” as “ball bushings.” This is messy.)

A deception: Place a sprocket—with bushing installed—on a properly-sized, horizontally-oriented, mounted shoulder bolt. Note that a shoulder bolt has a polished machine surface, much more uniform than the typical hex bolt. Spin the sprocket and note how freely it spins. If you witness this and are now convinced that the sprocket will impart little friction to the machine, you are misled. Once normal force (explained later) is applied when the system is under load, the friction will noticeably increase.

Proper bearings utilize cylindrical rollers (rods) or balls to greatly reduce friction. And this reduction occurs while the bearing can tolerate much greater loads and/or heat than a bronze bushing can tolerate.

When a block with a uniform surfaced is dragged across and in-line with another (complement) uniform surface, frictional force is resident. This frictional force is partly dependant upon the properties of the materials of both the block and the complement surface. For instance, the friction between stainless steel and stainless steel is different than the friction between mild steel and bronze. This specific relationship between two materials is denoted as the “coefficient of friction.”

Also important is the normal force between the two surfaces…that is, the force pushing the two surfaces together.

Typical friction is measured when the block has the tendency to move in-line with the complement surface. Friction is a force. The friction force is poorly defined on the ultrastructural level, but it is believed to be comprised of attraction bonds that are easily broken when the block tends to move out of line and away from the complement surface. The attraction bonds are greater when the block tends to move out of line and toward the complement surface.

For example, place a loops-side of Velcro® against the fuzzy counterpart. When pulled in-line, the surfaces are more difficult to separate, but when pulled away from the in-line orientation, they readily separate. This is why somewhat-worn Velcro is undependable when it winds around a corner and why it becomes somewhat more secure if you have a way to squeeze the loops side and the fuzzy side together.

Since proper bearings utilize the rolling of a ball or rod, the attraction bonds are continuously broken as the curvature of roller or ball surfaces leave the complement surface. The bonds are relatively easy to break although the normal force might be high. This is sometimes called “rolling friction”—a useful term although not technically pure. The so-called rolling friction inherent in proper bearings is to be contrasted with the so-called “sliding friction”—another quasi-technical term—that is common with articulations that translate rather than rotate.

Note (very important!): oil-impregnated bushings provide translational (sliding friction) to rotational articulations.

To reduce friction to the greatest, we must incorporate proper bearings. This is true for both rotational as well as translational articulations.

Note (also very important but not directly relevant here): human joints simultaneously rotate and translate!

Another early Nautilus design principle (or “imperative”) is that bearings were to be avoided. We believe that this very strong opposition to bearings originated with a machinist by the name of Don Peters, but it might have arisen from several sources. Regardless, this iron-clad bias affected Nautilus design policy for many years—throughout the 1970s and into the late 1980s.

There are two general kinds of bearings: radial and linear. Radial bearings are used for articulations that rotate, such as movement arms, drive wheels and redirectional sprockets. Radial bearings have the greatest application in an exercise machine.

Among the radial bearing designs there are those with rollers and those with balls. Most radial roller bearings are open, meaning that they are not sealed. Open bearings usually require messy lubrication as well as an inner race that is hardened to a standard that is Case-60. Open bearings are easier and less expensive to install than sealed bearings, but the standard shoulder bolt—though hardened—is not hard enough to serve as an inner race. The need for special hardening of the rods or axles serving as the inner race for each bearing would have increased the expense and complexity of Nautilus production.

Sealed bearings are pre-lubricated, are furnished with an integral inner race and do not normally require additional lubrication in exercise equipment. They are more expensive than open bearings, require precise boring for a press fit, and do not fit as well into tight spaces; however, sealed bearings can easily rotate on a standard hex bolt in most applications and are much cleaner in use.

Therefore, the ideal bearing for most exercise machine applications is the sealed bearing.

Sealed bearings were available to Nautilus throughout the company’s history, but they greatly increased the production costs—a cost apparently not deemed worth the added value to the product.

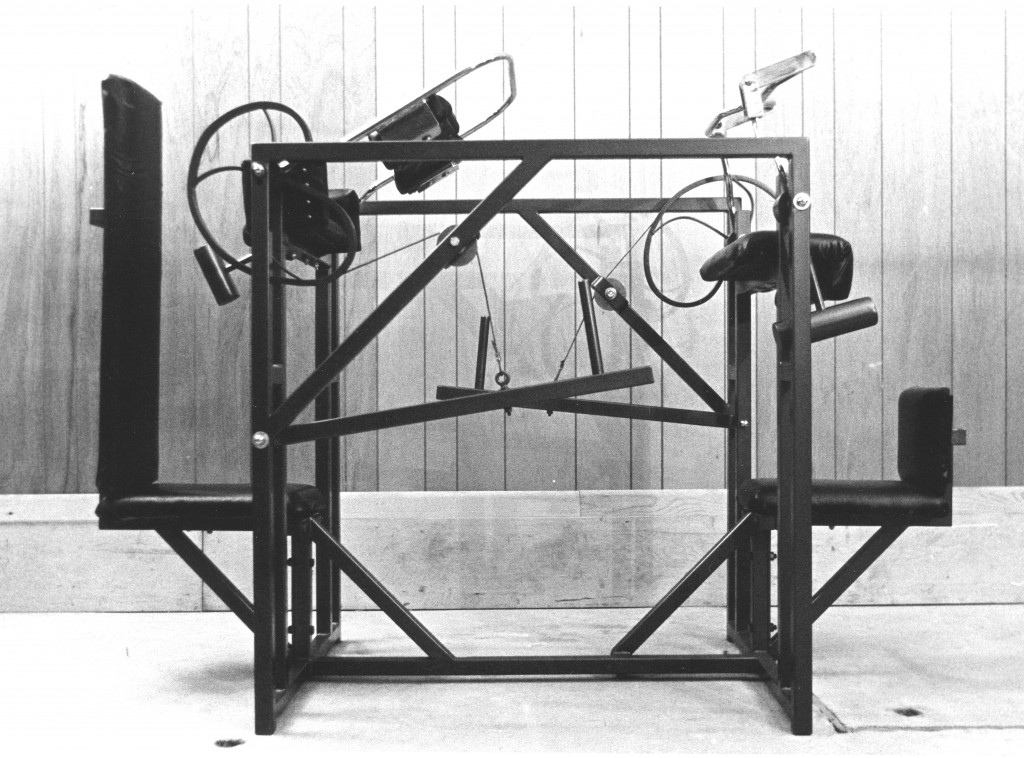

The cable-drive, Nautilus Plate-loading Biceps/Triceps machine (circa 1972)

Note that the earliest Nautilus Pullover and Biceps/Triceps machines—among several others—were cable-drive. All articulations were bushed. We should also acknowledge that these earliest machines had no weight stacks. (There was a transitional stage where some machines had cable drives and weight stacks that eventually gave way to most having weight stacks as well as chain drives.) For resistance changes, barbell plates were placed on pronged weight arms or in steel baskets.

One glaring—though well hidden—exception to the “no bearings” rule at Nautilus was the use of bearings in the movement arms of the Leg Extension and the Leg Curl. And realize that these movement arms presented great comparative effort and expense to bore the holes for a precise bearing fit.

The Nautilus Leg Extension I with the seat upholstery removed to expose the closed-chain system that enabled a remote cam and counterweight. With this approach, it was unnecessary for the cam and counterweight to reside between the knees.

There are two possible reasons that these movement arms received bearings. Our first guess is that this was done to save space between the subject’s knees. If bushings had been applied here, then the width required would have been an additional 0.75-1.25 inches between the knees to accommodate the head of the shoulder bolt and its lock nut on its opposite end. We favor this as the probable reason for the use of bearings in this location. The design was very elegant from a space-saving standpoint.

The Nautilus cable-drive Rowing Torso, circa 1972. The weight basket on this machine reciprocated on guide rods thus making the system work similar to a weight stack although not selectorized.

The other possible reason—still a good one—is that Scott and Arthur reached an impasse because of the formidable normal force imparted to these movement arms due to the remote cam and counterweights and their inherent closed-chain circuits. Apparently, bearings were unavoidable. What makes no sense with the excessive-normal-force reason for bearings in this location is that the workbox—housing the cam/counterweight/rear drive-sprocket assembly—incorporated no bearings! Apparently, reducing the friction by roughly one-half was good enough.

Perhaps the reasoning for using bearings in the Leg Curl and Leg Extension movement arms were two-fold, both for space as well as for friction reduction. Nevertheless, both issues were somewhat solved. (We invite any of the veteran Nautilus employees who might shed light on this mystery to contact us.)

To this day, the old guard reminisces about the “smoothness” of the original cable-drive Nautilus machines. As these machines did not have the familiar clicking sound of the chain going over the sprockets, they were much quieter. It is unlikely that anyone back then truly appreciated a machine displaying less friction as everyone moved very fast in the equipment. One must move very slowly in order to assess friction.

Over the years we have heard the assertion that there was significant friction due to the contact of the chain on the sprockets. Chain—also sometimes called “roller chain”—incorporates rollers that engage into the valley between the sprocket teeth. The chain links angle at the axis of each roller as they travel around a sprocket. As each roller is brought to bear into its valley, the impact makes a clicking sound. This engagement, its clicking sound, and the angling of the chain link are believed to cause meaningful friction. This is a myth. New or well-maintained chain—compared to cable or Kevlar—is messy, attracts dirt, grime and dust, and is difficult to maintain; but it is not a meaningful source of friction.

And note that “smoothness” as many of the old guard like to use in their devotionals to the old cable-drive equipment, does not indicate “low friction.” In fact, “smoothness” merely indicates uniform friction whether it is high or low. Note that hydraulic-based and gas-compression-based resistance sources are often very smooth, yet are entirely friction-based. We in the Nautilus hey-day were all wallowing in ignorance regarding our language and our understanding of these concepts. In order to make good decisions regarding exercise equipment design—or anything else in this world—we must apply precise language.

At Nautilus, once more sophistication was required in the equipment designs, cable no longer sufficed. As Arthur progressed beyond a few simple machines like the Plate-loading Pullover and the Biceps/Triceps, #40 chain began to replace the cable drives.

Seemingly, chain drives were required so that drive sprockets (different from redirectional sprockets) could be incorporated in high-load applications such as the entry/exit drive pedal for the Pullover or the remote cam assemblies for the Leg Curl and the Leg Extension. Unlike for cable, the drive sprockets provided the “teeth” for grabbing with the chain rollers. Cable connections might have suited some applications, but they were not as robust. Commercially, the product also needed a heavy-duty appearance, and cable just did not imbue an industrial image.

Note also that chain drives were far more expensive than cable. Once that additional expense was absorbed, a further additional cost of bearing incorporation throughout was prohibitive (or rather “profit-loss prohibitive”). Bearings would require the expensive boring of many parts. Their incorporation would also double or triple the cost of the sprockets.

In contrast, bushings were quickly installed into drilled—not reamed or bored—holes with a rubber hammer and with no attempt at proper alignment. Any misalignments were worn-to-alignment by the break-in period. One exception: bushings were probably precisely pressed into the redirectional sprockets as, in most cases, they came precision-bored from the factory.

Weight Stack Friction

In the early 1970s, no one yet seriously considered linear bearings for the weight stacks, but several voices attacked Nautilus on the basis of the bronze bushings incorporated into the redirectional sprockets and other rotational parts. Later, Cybex® exercise equipment—then known as Eagle®—for instance, used cable drives with bearing articulations in plastic pulleys. (The early Nautilus cable-drive machines had no bearings in the redirectional sprockets.)

After years of disparaging Cybex equipment, Ken Hutchins first experienced a Cybex-Eagle Trunk Extension machine and muttered, “Why can’t we at Nautilus have this?” Ken was referring both to the machine design—the Eagle incorporated an adjustable pedestal whereas the Nautilus Lower Back machine did not—as well as to the low-friction excursion due to bearing incorporation throughout (except for the weight stack).

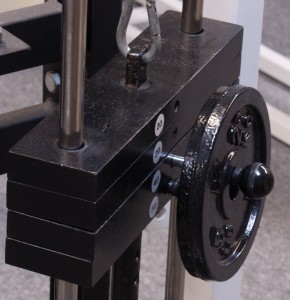

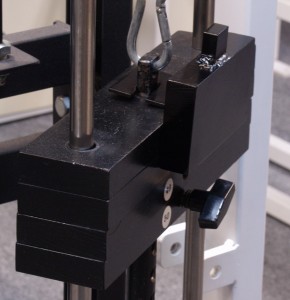

Weight-stack friction was overlooked for a long time merely because all other articulations were so blatantly friction laden. Once Ken understood more regarding normal force and its place in the friction equation (Ff = µFn where Ff is friction, µ is the coefficient of friction, and Fn is the normal force.), he continued to deliberately disregard the issue of weight-stack friction. He did this for a theoretically correct reason: a weight stack, in theory, possesses no normal force between its articulations (guide rod and weight plates), therefore it has no friction. The common exception, however, is that the theory rarely holds up in practice due bent guide rods, non-plumb weight stacks, tolerance mismatches, and a host of other details now completely and exclusively addressed by the UltraGlide® weight stacks in the new RenEx® exercise equipment. (All of these factors are thoroughly detailed in the Renaissance of Exercise—Volume II, due to be published later in 2012.)

A laughable approach to reducing weight-stack friction occurred during the early 1980s at Nautilus. This is laughable for several reasons. First, the Nautilus engineers blamed the least culpable factor for the friction excesses; they continued to produce thousands of machines with bushings throughout all the other articulations. Second, belated and misdirected priority to correct the weight-stack friction caused more, not less, friction as you will soon appreciate. Apparently, the names of the crack Nautilus engineers were Larry, Curly, and Moe… and they took their direction from the omniscient, fearless leader, Arthur Jones.

For several years, Nautilus produced “improved” weight stacks incorporating linear bearings in the top plates. This potentially huge technological leap failed to span the gorge. Instead of using the required Class-L steel rods for guide rods, Nautilus incorporated the usual stainless steel (304) rods. Although 304 stainless is harder than regular mild steel, it is not the required Case-60 hardened. This led to deep scoring on the guide rods caused by the circulating balls in the linear bearings and noticeably greater friction.

The rod scoring exposes other issues. Although a weight stack, in theory, has no normal force, Nautilus’ use of linear bearings introduced dramatic normal force. This occurred, because the 304 stainless rods were often too large for the bearings. The proper Class-L rods are—in addition to being the proper hardness—also of accurate, precise, and uniform dimension for the linear bearings.

Of course, the weight-stack fiasco cost Nautilus tens of thousands of dollars to correct. Plastic bushings were eventually used instead.

Shortly after this, Gary Jones attacked the problem from another direction. As shown already, the friction formula has two factors. One is the normal force. The other is the coefficient of friction. Gary noted the extremely low coefficient of friction between Teflon bushings and polished stainless steel. He tried to get these into production, but cheaper plastic bushings were eventually adopted instead. Gary’s attempts in this area had a great impact on Ken’s early treatment of the weight stack issues. Initially, it gave Ken more justification to disregard the weight stack as a meaningful culprit.

Add-On Plates

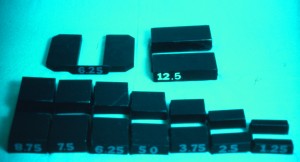

The only way to make in-between increments before ~1980. Note that there was no way to do this between 30 lb and 40 lb in this particular case. In other cases, it was impossible between 20 lb and 30 lb—exactly where it is needed the most.

Another weight-stack issue came to a head at about the same time. Most of the Nautilus machines used weight stacks incorporating 10-pound plates. This meant that there was no Nautilus-provided means to progress the weight in smaller denominations. A 10-pound progression was a 5% graduation (commonly recommended) if a subject was using 200 lbs (the entire weight stack on some machines) and was a 50% increase for the typical woman using 20 lbs. The only solution for the first decade of the Nautilus company was to pin a barbell plate to the side of the weight stack—of course that selected part of the weight stack. This cocked the selected weights, introducing friction somewhat like a brake.

Sometimes the cocking of the selected weights was so severe that the stack pin would abut the top of the unselected stack. Then the instructor would correct this by pulling free the stack pin. This would release the supported weights, risking crushing his hand. At the very least, the subject was jolted when the weights released.

This was Nautilus’s first attempt to solve the need for smaller denominations. This poor solution was mass-produced. Note that it did free up the selector pin somewhat, but remained useless for amounts between 20 lb and 30 lb. The imbalance to the stack pin and its resulting friction was almost as bad as using the pinned-barbell-plate method.

In the early 1980s Nautilus finally responded to this problem by making an add-on plate in three different denominations—2.5 lbs, 5 lbs, and 7.5 lbs. These failed to solve the problem, because they were made to hang off the side of the selected weight stack just as a barbell plate had done earlier, thus cocking the selected weights. The only improvement was a tang that hooked around the top of the stack pin that obviated the use of an additional selector pin. Still, it canted the stack pin and caused additional friction onto the guide rods. It continued to interfere with the selector pin when selecting lesser weights. In addition, the tang might go into a subject’s chest if he was so unlucky as to fall onto it.

Was this the best that all the brains at Nautilus could do about this problem after 10 years? Or were Nautilus machines only for brutes who didn’t require the recommended 5% jumps?

Especially for the Nautilus Osteoporosis Research Project, Ken had a Nautilus machinist make these to his specifications. These incorporated a steel connection band that was so weak that they required careful handling lest they deform when accidentally dropped on the floor. They did the job. Note that the larger ones were needed for the larger plates used on the Nautilus Squat machine. Ken quickly noted the dangers of the Squat machine and sent it back to the Virginia plant.

While the Nautilus Osteoporosis Research Project was pending throughout most of 1982, Ken realized that none of these

pathetic approaches at smaller increments would suffice for weak, elderly, fragile, osteoporotic women. So Ken approached a Nautilus machinist with the problem, and the workable prototype add-on plates shown here were quickly made.

Ken then showed the problem and the prototypes to the manager of the Virginia plant who stated that such were impossible to mass-produce. Ken then went to Arthur who quickly directed Ken to show them to the Virginia plant manager. Hearing Ken complain that he had already been turned down by the plant manager, Arthur raised his eyebrows and said, “Give ‘em to me. I’ll take care of it.” Of course, Ken had to have the machinist make another set for the study.

The final product was cast iron.

Sometime after the Osteoporosis Project got started in late 1982, Nautilus began offering sets of the cast iron add-on plates pictured here. This product did the job. It’s amazing, now, to reflect upon the thousands of Nautilus facilities—commercial, military, university, private, industrial, medical, public school—that were placed into operation since the inception of the company without access to this simple remedy for smaller resistance progression. Moreover, few users—subjects and instructors alike—ever considered the additional friction caused using any other approach. We guess that a great way to cover up the deficit in the negative backpressure due to excessive friction was to stay with the promotion of emphasis on the negative excursion.

The Nautilus Nitro double weight stack system. This main stack (right) has 20-lb graduations and its side stack has 5-lb graduations. It is extremely friction laden, especially if the side stack is engaged.

Almost 30 years later, Nautilus continues to apply the same nonsense to their Nitro line as they did throughout the 1970s. The only difference—besides blocking access to the primary selector pin—in effect, between hanging the barbell plate off the side of the selected stack and the use of the Nitro side stack is that the weight is now selectorized. The side stack still produces the cocking force on the main stack pin and exorbitant friction.

It is common for an intelligent instructor to forego the side stack and use properly-designed add-on plates atop the main stack. Even then, undesirable friction is added by the side stack merely with its top plate and stack pin. This could all have been solved if the engineers had correctly incorporated linear bearings. Of course, the argument against making it correctly is that the machine will no longer cost the manufacturer within the allowable price point—a poor reason for making an inferior product, in our opinion. By the way, it was visually-appealing craftsmanship.

Note that the same tendency of stack-pin cocking—though completely solved by the RenEx designers by the use of linear bearings—is resident in the RenEx top plate when the endpoint delimiter is engaged. We were warned that such a device would cause the weight stack to seize once a heavily canted load was applied. Seizing does not occur.

Even in his 41-page confidential treatise to Arthur Jones in May of 1986, Ken failed to mention the weight stack as a friction source. Then, Ken focused on three major concerns: the magnitude of friction inherent in the movement arms and in the redirectional sprockets and the effect of friction on the desired resistance curves and the effect of friction on the differentials between positive and negative loading. Ken therein asserted that the elimination of most of the friction would greatly alter the resistance curves. He also asserted that the friction minimization would improve the ratio of positive to negative phase loading by hundreds of percent.

In one example, note that the friction in the Leg Press function of the Nautilus Compound Leg was such that at 30, 40 or sometimes 50 lb, the movement arm would stick in place several inches above bottomout. Therefore, what is the improvement of load in going from zero to any positive number? Answer: an infinite percentage improvement!

Ken sent the friction treatise to Arthur in May 1986. Several days later, Ken phoned the Nautilus pavilion in Ocala to speak with Inge Cook (company photographer and eventually Arthur’s sixth wife) as she planned a photographic shoot of the Nautilus testing equipment that would become MedX. The pavilion was a large room where the 1986 Twin Study was also being conducted.

Arthur answered the phone. Ken identified himself and asked to speak with Inge. Arthur answered: “She’s right here… [as Arthur was handing the phone to Inge] Oh, by the way, Ken, I read that paper you wrote and you don’t know crap about friction. Come over here and I’ll explain it so that you can understand it.” Ken answered with his usual, “Yes sir. I will be over there to assist Inge at the end of the week and we can talk then.”

Ken became very sensitive to Arthur’s put-down. He began to mull over his paper and wondered what part or parts of it that Arthur was going to gig him for. Ken began to focus upon his explanation of so-called “rolling friction” and suddenly realized that his concept and explanation of this—devoid of the discussion of the theorized attraction bonds—was specious. He had explained rolling friction on the basis that rods and balls involve less surface area. This was an embarrassing mistake since there is no place for surface area in the friction formula! Continuing to believe that Arthur understood physics far beyond Ken’s grasp, Ken shuddered to imagine how Arthur was going to excoriate him once they began to talk. Otherwise, Ken was solid on the general conclusions of his paper.

A few days later, Ken and Inge drove from the Lake Helen Nautilus headquarters to the Ocala pavilion and began setup for more photography. The din of the place made hearing a challenge as the Twin Study was in process. The weight stacks on the machines were blocked, making so that the subjects—moving at a ridiculous speed—slammed the weights into the top of the machines and then into bottomout. Their instructors were grossly incompetent. And the study was asinine. Ken tried to ignore it.

Arthur motioned for Ken to join him around a prototype-testing machine, and Arthur directed a technician to pull up a stored performance graph onto the computer monitor. The chart displayed the tracking of a subject’s positive excursion plotted against the tracking of the negative.

Arthur then said to Ken, “See the difference between the registered force tracks? The chart shows an approximate 40% difference between the positive and negative force outputs from the muscle. This difference is due to friction in the muscle. I don’t know where the hell you come up with those outrageous numbers you published in your paper where you state hundreds or thousands of percent, but this is what you should be looking at!”

Ken replied, “Arthur, you supposed this over a decade ago in your writings, and it’s great that you can now accurately measure and display it, but this is not what my paper is about. I am talking about the exorbitant friction in the machines, not that of the body.”

Arthur continued: “Well your numbers are way off. They’re outrageously flawed and inaccurate.”

Ken again, “In my paper I discuss theoretical models. They are not necessarily applicable to every situation, but they are, in essence, correct.”

Arthur began to appear to lose his patience and moved away from Ken, getting distracted by other activities in the room.

Ken remained pretty much at attention for a short while just in case Arthur would to come back with more protest. During this time Jim Flanagan came up to Ken and advised, “Ken, just say ‘yes sir’ and ‘no sir’ and agree with him. You have nothing to gain by aggravating the man.”

Ken: “He is wrong this time.” Then Ken walked over to resume helping Inge.

Arthur never mentioned Ken’s mistake regarding the weakness of his explanation of so-called “rolling friction.” Ken concluded that Arthur did not understand it himself. If so, Arthur would not have missed the opportunity to grill Ken on the subject.

A few days later, Jim drove Ken out to a secluded area just beyond the Lake Helen city limits. He and Ken talked a while. Jim had a sincere message of caring for Ken. He said, “Ken, you must not ever correct Arthur.”

Ken replied, “But Arthur has always strongly stated that if he is wrong about something, he is the first one that needs to hear about it. And I carefully ensured that this sensitive information was transferred confidentially to him. It was Arthur that brought it out into the open amidst all the audience we had around us in the pavilion.”

Jim: “He says that he wants correction when he is wrong, but this is not really true.”

A few days later, Arthur fired Ken, and then another few days later he sold the company. Apparently, Arthur feared Ken mucking up his sales job on the prospective buyers.

Later Ken built the SuperSlow Systems equipment, but did not focus on the friction problems of the weight stack until Gus Diamantopoulos helped him to see a way to reevaluate the application of linear bearings. From there, the RenEx team took on the myriad other issues inherent in weight stack design and manufacture.

Back to Front

It may seem that we have diverged some, if not excessively, to delve into the friction issue. This study of friction, however, is deserved. It is paramount that this arcane subject be brought out into the sunlight so that all of us can ruminate on its multiple effects upon the efficiency of exercise equipment. And this is especially relevant with regard to the dumpers. If we minimize friction and incorporate the correct resistance curves and move at the 10/10 excursion speed, then the dumpers really contribute nothing to productive exercise. What’s more, the dumpers create and perpetuate problems that we will explore more in subsequent installments of this series.

Reflect on this: Some of the heyday Nautilus insiders once hypothesized that it was probably impossible for Casey Viator to train himself and to obtain good results on Nautilus equipment, because Casey knew every trick to beat the machine and, therefore, obtain unloading. At the same time, much of the bodybuilding community complained that Nautilus was a sham and didn’t effect as good results as the barbell. We know that most of these complaints were merely due to the ignorance that many bodybuilders possessed regarding proper training principles; however, the excessive friction in the Nautilus equipment was a concrete, albeit unrecognized, reason for their charges.

Recently, at dinner, Ken Hutchins complained to Drew Baye that it was outrageous that he and the RenEx team had had to fix all the weight stack problems. Ken said/asked, “I am, of course, proud that we were finally able to do this, but why us? Why has this taken 40 years to accomplish? Why didn’t Arthur and all his millions and minions fix this? Why—though the engineering technology and machine products were readily available decades before Nautilus—did it require us to finally get this done? Why was it not done by Nautilus after Arthur sold it? Why did MedX not fix the problems?”

Drew answered, “I guess because they did not know they needed to fix them.”

In Dumpers, Part III, we will explore two interrelated factors—resistance curves and excursion speed—that deceive subjects and instructors into the belief that a hyperloaded negative improves training effect.

The negative is no more or less important than the positive (or any other part of the rep), but people have been mystified into believing that it is. This is because of unrefined/unexamined protocols, friction-laden equipment, and a failure to recognize the primary objective of exercise.

The negative is no more or less important than the positive (or any other part of the rep), but people have been mystified into believing that it is. This is because of unrefined/unexamined protocols, friction-laden equipment, and a failure to recognize the primary objective of exercise.